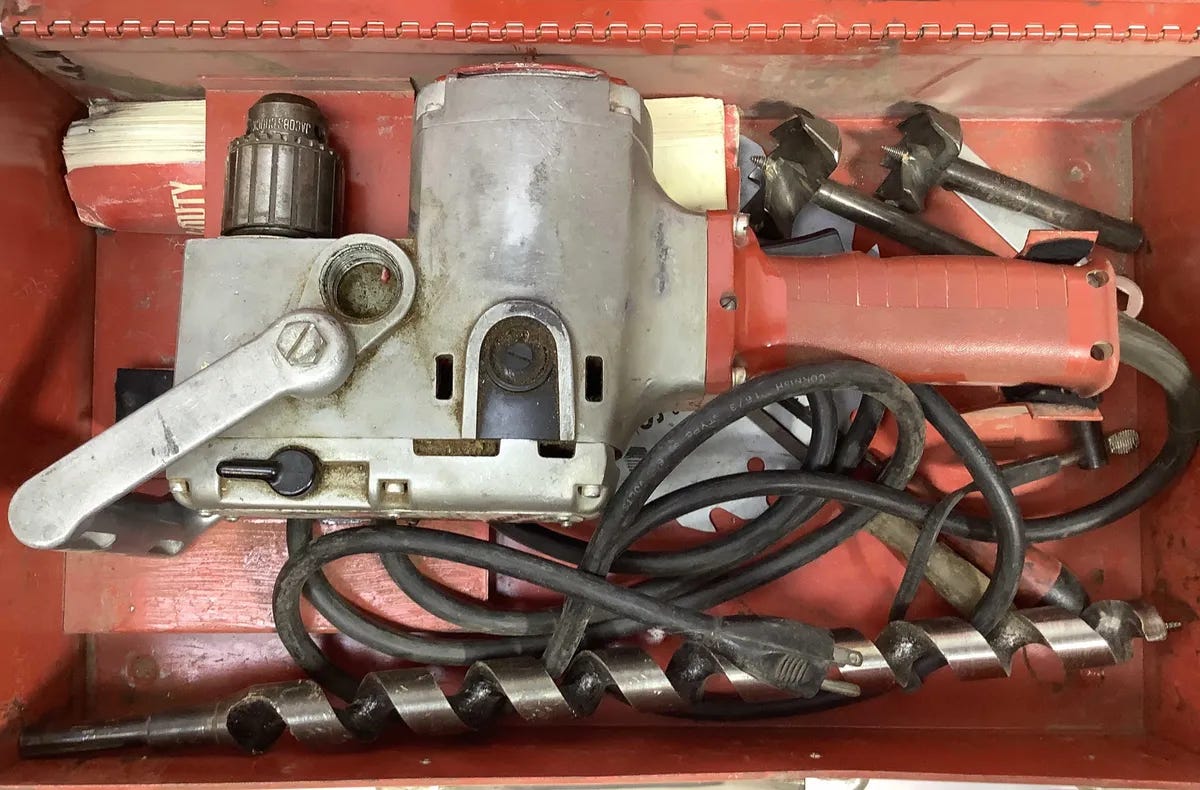

On every construction site in America, there is at least one Hole Hawg. The contractor bought it used in 1997. The one in the photo above is a rare sight indeed, because it still has its original plug. Most Hole Hawgs have a yellow replacement NEMA-type connector on them, and the cable itself is more electrical tape than factory insulation.

Hole Hawgs are made by Milwaukee (the tool company, not the city). They come in a metal carrying case instead of plastic, because the tool itself weighs 45 pounds and requires a sturdy, metal box. The box is usually dented because someone dropped the Hole Hawg on top at least once. The latch has a 50% chance of being broken and useless.

Every green construction worker, regardless of trade, will someday have to go to the tool crate and retrieve the Hole Hawg for use. It can drill through wood like butter, and running wires or pipes through wooden joists requires agile and careful work with a Hole Hawg and an equally intimidating auger bit. This is not a chuckless design, and great care has been taken over the years to keep the original chuck on the extension cord. If you’re the one to lose it, you might as well quit. No one wants to be near you, you stink of failure.

The Hole Hawg smells like grease and sparks, and there is a thin layer of oil-soaked wood dust clinging to every edge of the metal. And there’s a lot of metal.

100% of the time you use a Hole Hawg, you have to use it over your head on an 8-foot or higher ladder. As you’re setting up to use it, the oldest guy on the jobsite will come up to you and tell you about how he watched a fella have his arm ripped completely off when the Hole Hawg bit bound up on him.

You see, the Hole Hawg is pure torque, so when the bit encounters something (adamantium perhaps) that makes it stop spinning, all that power is instantly transferred to the tool, so instead of spinning the bit, it will just spin you instead. Effortlessly. It is a cold and unfeeling brute.

The best way to avoid becoming someone’s anecdote of warning is to brace yourself with every trigger pull, pushing against its rotation with all your might. If you get the technique right, it will just give you a little love tap rather than twist your arm like a sociopathic schoolyard bully.

Since the Hole Hawg is only used above your head, your arms will be exhausted and your legs shaky from trying to keep balance atop a ladder. Best of all, the large, curled wood shavings from your drilling will all fall down the back of your shirt, causing bonus discomfort.

If the jobsite is still on temporary power, the breaker will trip every 30 seconds, requiring you to get down from the ladder with the Hole Hawg and walk across the site to reset it. If you leave the Hole Hawg on the ladder while you walk to the breaker panel, you are worse than Hitler.

The modern Hole Hawg is smaller, more agile, easier to fit between joists, and still has the same power to knock your head off. But no one has ever bought a Hole Hawg. They simply exist in every company’s tool collection, and always will.